Our metal stamping assembly services provide a variety of secondary processes required to provide finished metal parts and assemblies ready to use in your manufacturing process. D&H performs many finishing operations, including heat-treating, cleaning, deburring, riveting, hardware insertion, countersinking, tapping, and other machining operations. When you have requirements for a specific process that we do not currently perform in-house, we will research the feasibility of adding that process or turn to one of our sister companies or local supply partners.

From simple two-piece assemblies to complex multi-level assemblies, D&H’s manufacturing team is capable of providing products to your exact specifications. Beginning with an ERP system designed to manage multi-level bills of material, we can perform a wide variety of assembly, supported by a manufacturing and quality staff dedicated to your specific needs.

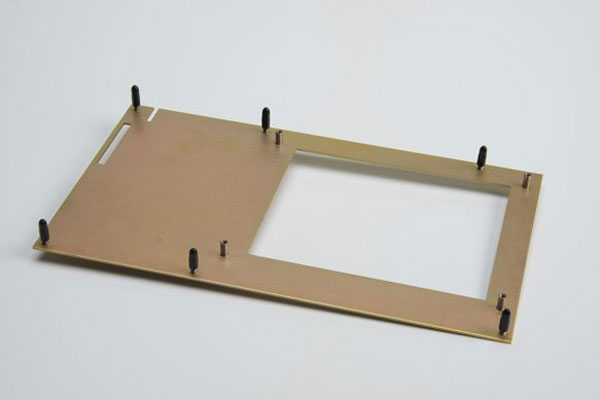

Machined components and hardware (mechanical fasteners and press inserted) are combined with precision stamped parts to yield a complete ready-to-use assembly.

In-House Value-Added Services: PEM insertion, countersinking, labeling, tapping, deburring, milling, and drilling

Managed Processes: annealing, anodizing, austempering, Blanchard grinding, heat treat, painting / E-coat, plating, stress relieving, tempering

Assembled Panel

Machined Parts Fabrication

Stamped Part with Seal

Assembly with Threaded Posts